With today’s energy efficient, tight homes, mechanical ventilation is required to provide fresh air and prevent moisture, odor and other pollutants to build up. The 2015 IECC and Massachusetts Stretch Energy Code recognize this as an important step in protecting both the homes occupants and the home itself.

Benefits of Mechanical Ventilation

Properly installed mechanical ventilation provides healthier indoor air quality, an increased ability to control the amount of ventilation needed, and improved home comfort.

Mechanical Ventilation Basics

Mechanical ventilation is available in three different types:

Supply-only

Exhaust-only

Balanced ventilation

We very seldom see supply-only ventilation since it will pressurize the home, possibly push warm moist air through the exterior wall system, and cause potential condensation issues on the exterior sheathing.

Exhaust-only ventilation is often used with specially designed bathroom ventilation fans that are quiet and operate 24-hours a day with very low power consumption.

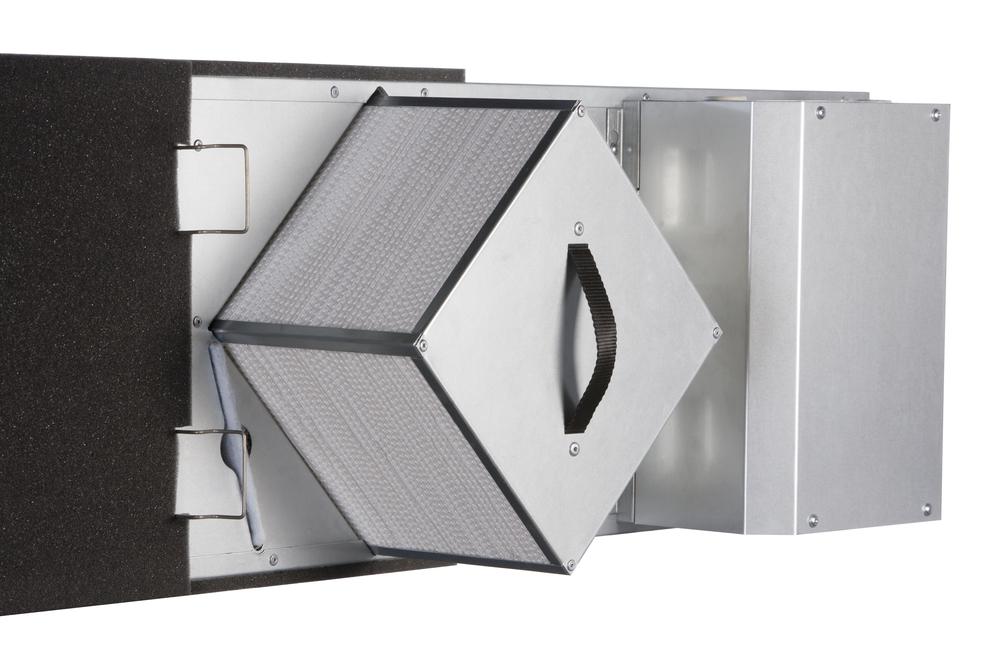

The last option is balanced ventilation. Balanced ventilation is the preferred option to provide mechanical ventilation and when installed properly, it provides ventilation while at the same time capturing heat from the exhausted air and applying it to the fresh incoming air without mixing the two air sources. Balanced ventilation will not cause condensation issues in the exterior wall cavity since all incoming and outgoing air travels through the ducted pipe system. With balanced ventilation, typically as much polluted air is removed as the same amount of fresh air is supplied, thereby not causing any pressurization or depressurization in the home.

Balanced Ventilation Systems

Balanced ventilation systems are found in two formats:

HRV – Heat Recovery Ventilation

Captures some of the heat from the exhausted air and applies it to the incoming fresh air.

ERV – Energy Recovery Ventilation

Captures some of the heat and moisture, and applies it to the incoming air.

Massachusetts Stretch Energy Code and the 2015 IECC require that mechanical ventilation has a power consumption of 1 watt per 2.8 Cubic Feet of Air (CFM). Therefore, not all ERV or HRV systems can be installed in Massachusetts. Typically, only some mechanical ventilation with an ECM (Electric Commutating Motor) is able to meet the limited power consumption required by the energy code.

Installing an HRV or ERV the Right Way

The proper installation and configuration of an ERV or HRV is critical. Many systems are installed by connecting the system to the return duct of the HVAC system to reduce installation time and ductwork. When installed in this way, the furnace air handler may need to operate when the mechanical ventilation is needed. That could be as much as 24 hours a day and therefore increase the total power consumption and the wear and tear on the furnace air handler.

To make mechanical ventilation and HVAC systems operate properly, it is best to install the two as two individual systems (standalone ERV/HRV) and not have any connections between the two duct systems.

|

|

Typical HRV install | HRV installed with fresh air supply installed to return duct of HVAC system |

Infrared Diagnostic provides commissioning of installed mechanical ventilation systems and is available for consulting, testing and evaluation of mechanical ventilation.